The Covid-19 crisis has accelerated digital transformation in manufacturing significantly, as businesses had to get used to supply chain disruptions, remote work and new delivery methods. If there was one thing that the whole manufacturing industry learned in the year 2020, it is that investing and adopting the latest technologies is not just a yes or no choice when it comes to streamlining processes and ensuring business survival.

Latest technologies are helping manufacturers to reduce costs, optimize the process, enhance the quality of the products and boost the overall productivity of the workforce. There’s no doubt that many companies have started to realize the long term benefits of digital transformation. You, too, can benefit greatly from going digital. This article will tell you some of the reasons why a manufacturing company should invest in digital transformation, as well as show you top 10 trends to watch for in 2021.

For a manufacturing business to be more efficient and effective, there is no choice but to focus on innovation and technology. Today’s digital manufacturing can benefit you in these 6 ways:

- Improve efficiency & productivity: The next level of traditional manual processes is cloud-based solutions, which will help improve your decision-making capabilities, avoid costly rework and downtime, simplify performance monitoring, identify weaknesses and bottlenecks, and so on. This way, your business can save a huge amount of time and money while also becoming more effective.

- Reduce costs: Digital manufacturing can help you get a better insight into issues, such as inventory levels, delivery status, and demand cycles. This will minimize unnecessary risks and costs related to problems like excessive inventory and material.

- Innovation: It is worth it to invest in the right digital technology and software, as it will equip your employees with unique and improved skills.

- Customization: Digitized manufacturers can provide customers with attractive customization options. It also allows manufacturers to expand on a mass scale while maintaining high efficiency.

- Safety: Robots can work in dangerous environments. The manufacturing staff can be alerted about potential hazards well in advance.

- Attract and empower the next generation of workers: By investing in digital technology, it gives you a better chance of attracting and retaining skilled employees.

Getting back to the topic at hand, let’s explore the top 10 trends that will rule the manufacturing industry in 2021 and how each one will play a role in defining the digital transformation journey of the industry.

1. IoT (Internet of Thing)

IoT is not something new but it is still trending in 2020 and will continue to do so for the next few years. IoT is now globally applied and companies are understanding its important role. IoT helps you connect different types of devices from anywhere via the internet to conduct tasks automatically and to make decisions in real-time, based on the data available at hand. You can manage the supply chain, detect the quality of the parts, find the origin of any defect during production, ensure the safety of the employees and perform various other functions with the help of IoT.

2. Big Data and Predictive Analytics

With the development of technologies like IoT, companies are greatly investing in their cloud-based capabilities and building an infrastructure that is able to collect data from every state of the manufacturing process. Having data in hand will help you reevaluate your strategies and understand your business clearly and give you a better sense of timing. But having data is one thing and making it meaningful and useful is another. Therefore, collecting the real-time data of every device in the plant is necessary to predict when a specific device might turn off and at what point it may still need to be connected. Predictive analytics help avoid downtime periods and manage the plant in a much better way.

3. 5G

5G has been around for a while but manufacturers should use it effectively to improve the smart manufacturing ecosystem. It offers high-speed internet connection, permits faster communication, and saves valuable time. Also, it helps manufacturers use multiple sensors on different types of devices, improves the cloud infrastructure, enhances the identification of parts, and maintains the quality of the product.

4. Digital Adoption Platform

There are a lot of things taking place in the backend, from handling inventory to procuring raw materials. These functions can be complicated when the workflow is so high, especially when it comes to entering details within the procurement application.

Manufacturers might deal with the problem of how to conduct those tasks efficiently while ensuring the accuracy and integrity of the data, which is simultaneously of paramount importance. A digital adoption platform, therefore, is an ideal solution to train your employees while keeping them engaged.

5. Smart Industrial Robots

Production automation and robots are not something that factories are unfamiliar with, but being able to adjust them quickly with complex changing conditions is new. Responding to an increase in customer orders or needing to lower machine performance in one part of the factory, is something the control systems and programming languages can handle.

With the advent of robots in conjunction with AI and other emerging technologies, manufacturers can take a critical step towards transforming into intelligent factories. At this level, robots not only perform tasks, but are also able to engage in data collection, sharing and analysis to work on solving human induced problems. Additionally, collaboration robots; cobots, will emerge to help humans accomplish tasks in dangerous environments, thereby allowing a human to work safely and at a smarter distance.

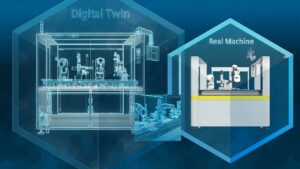

6. Digital Twins

A digital twin can behave as a device’s real-life equivalent to collect data on the most effective solution as manufacturers digitally replicate different scenarios. Manufacturers can also improve quality of goods, design predictive maintenance, optimize production processes and risk mitigation scenario planning by combining digital twins with IoT data and AI.

7. AR/VR

In order to improve the production floor’s performance, manufacturers are also running alternate reality/virtual reality (AR/VR) applications by using 5G and edge computing. With this technology, employees can assemble a product or repair a machine within a real-time feedback loop to confirm that it was done correctly through AR/VR support and guidance. In the case that it’s not fixed immediately with the step by step correction instructions, AR will inspect all locations, making sure every part is in the correct location or position, and run through the quality criteria.

8. 3D Printing Technology

3D printing technology is a much talked about form of digital transformation in the manufacturing industry. This technology helps companies make faster and cheaper prototypes. In fact, the use of 3D printing helps to halve costs while delivering twice the performance. It’s a cost-effective way for product designers to troubleshoot and test their commodities. It also helps manufacturers produce commodities that are in high demand.

9. Predictive Maintenance Innovation

In the past, if there was any malfunction that was unnoticed, manufacturers would schedule routine maintenance checks on equipment. This work would disrupt the production process and cost money. Now, with the development of digital technology, machines are equipped with internal sensors that send messages automatically to alert workers if maintenance is required. With a real-time notification and response system, the technology of predictive maintenance recognizes mechanical failures before they even happen.

10. Agility and Responsiveness

One of the biggest advantages of the new need for digitalization, is that technology is making manufacturers focus on bolstering responsiveness and agility due to changing customer demands and market conditions. This is beneficial to the manufacturing industry. Matching production cycles and emerging product demand levels can be closely monitored. The more successfully an organization can match those two essentials, the more agility it can pump into its operations.

New technologies will be invented, and the existing ones will be innovated. Consumer needs are increasing with every passing day and companies are competing with each other to satisfy those needs. New technologies will be of paramount importance so your manufacturing business needs to realize the long term benefits of digital transformation and have a good strategy in place in order to successfully go digital.

Contact Kyanon Digital today for more detail and information.