In today’s fast-evolving industrial landscape, manufacturing digital transformation is no longer optional—it’s a necessity for survival. As global supply chains become more complex and customer demands shift toward hyper-personalization, manufacturers must embrace digitalization to stay competitive.

What is digital transformation in manufacturing? Manufacturing digital transformation refers to the integration of advanced technologies—such as AI, IoT, cloud computing, and automation—to enhance efficiency, agility, and decision-making. It’s about moving from traditional, siloed operations to connected, data-driven, and intelligent production ecosystems.

- From legacy to smart factories: Traditional factories relied on manual processes and isolated systems. Digital transformation introduces real-time data analytics, AI-driven automation, and smart manufacturing solutions.

- From reactive to predictive: Instead of waiting for equipment failures, manufacturers can now predict and prevent breakdowns using AI-powered predictive maintenance.

- From static to agile supply chains: Digital twins and cloud manufacturing enable real-time tracking of materials and supply chains, making operations more resilient and responsive.

Further reading:

- Top 10 Digital Transformation Challenges In Manufacturing

- How Has Covid-19 Changed The Manufacturing Industry?

- Reimagine Smart Manufacturing and Supply Chains with Low-Code

The Growing Importance of Digitization: Today and Beyond

The Fourth Industrial Revolution, known as Industry 4.0, has reshaped how companies manufacture, improve, and distribute their products. Manufacturing digital transformation has introduced digital manufacturing transformation technologies that enhance predictive maintenance, automation, and process self-optimization.

The ultimate goal is to enhance productivity, reduce waste, and improve decision-making through data-driven insights. As more companies embrace digital transformation in the manufacturing industry, the global Industry 4.0 market is projected to grow from USD 130.90 billion in 2022 to USD 377.30 billion by 2029 (Fortune Business Insights), reflecting the rapid adoption of innovative solutions in manufacturing.

With the proliferation of technology suppliers and advancements in data and analytics, artificial intelligence, and machine learning, manufacturers have access to hundreds of possible tech applications and solutions to enhance their workflows.

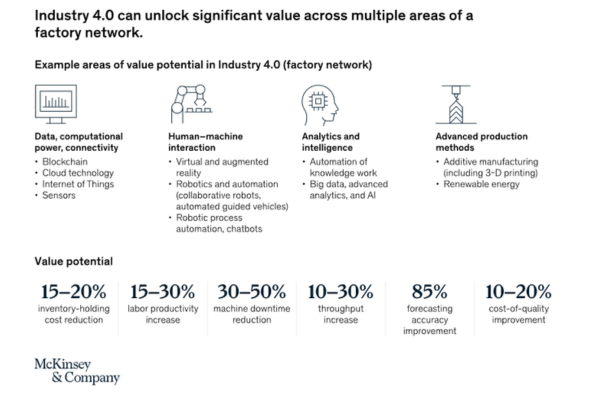

When properly implemented, these solutions yield unstoppable benefits. In a variety of industries, it is not unusual to observe 85 percent more accurate forecasting, 10 to 30 percent increases in throughput, 15 to 30 percent increases in labor productivity, and 30 to 50 percent reductions in machine downtime.

Example areas of value potential in Industry 4.0 (Source: McKinsey & Company)

Digitization is also revolutionizing supply chain management. With data-driven production, companies can customize products more efficiently, directly influencing production lines. By merging physical and digital data, businesses create more agile and efficient supply chains that adapt to changing demands.

Beyond efficiency, digital industrial transformation helps break down internal silos that may hinder growth. Companies can leverage real-time data across the value chain, from suppliers to partners, ensuring smoother collaboration. Digitizing and automating manufacturing processes not only improves product quality but also reduces rework and enhances profitability.

As digital transformation in the manufacturing industry continues to evolve, businesses must keep pace. By embracing digital transformation trends, manufacturers can prevent costly errors, optimize workflows, and enhance worker efficiency. Today, many manufacturers rely on advanced technologies—from factory automation to data analytics—to drive innovation and maintain a competitive edge.

Top 10 Trends in Manufacturing Digital Transformation

1. Digitalization and Industry 4.0

Manufacturing digital transformation has revolutionized the industry, helping businesses optimize processes, enhance quality, and reduce costs. Industry 4.0—also known as the Fourth Industrial Revolution—is a key driver of this change, bringing digital manufacturing transformation to the forefront. It integrates advanced technologies such as the Internet of Things (IoT), artificial intelligence (AI), and cloud computing into manufacturing operations.

The impact of Industry 4.0 is massive:

- IoT adoption in manufacturing is expected to reach $87.9 billion by 2026 (MarketsandMarkets), underscoring its role in driving real-time data collection, predictive maintenance, and automated decision-making.

- AI-driven predictive maintenance could save manufacturers up to $630 billion annually by 2025 (IoT Now), reducing downtime and optimizing asset utilization.

- The global IoT in the manufacturing market is expected to grow from USD 50.0 billion in 2021 to USD 87.9 billion by 2026, at a Compound Annual Growth Rate (CAGR) of 11.9% during the forecast period (MarketsandMarkets)

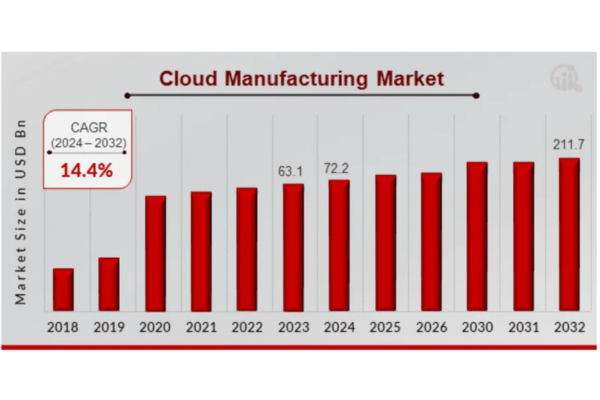

- The market size of cloud manufacturing was assessed at USD 63.1 billion in the year 2023. The cloud manufacturing market is anticipated to expand from USD 72.2 billion in 2024 to USD 211.7 billion by 2032, demonstrating a compound annual growth rate (CAGR) of 14.4% throughout the forecast period from 2024 to 2032. (MarketsandMarkets)

- 87% of manufacturers use cloud solutions in their business strategies. (Forbes)

Cloud manufacturing market (Source: Market Research Future)

Case Study: BMW with Smart Factories & Digital Twins

BMW has implemented digital twin technology in its production facilities, creating real-time virtual models of its manufacturing plants to enhance operational efficiency and reduce costs.

The BMW Group manufactures 2.5 million vehicles annually, with 99% of these cars being customized by customers. This presents intricate manufacturing challenges. In order to maintain its competitive edge, the automobile manufacturer is employing real-time simulations of entire factories to enhance production workflows. (NVIDIA)

AI-enabled digital twins help the automaker improve operational efficiency in factories and reduce costs.

2. Artificial Intelligence (AI)

One of the most significant advantages of AI in manufacturing is its ability to analyze vast amounts of data in real-time. With Industrial Internet of Things (IIoT) devices and sensors collecting data from machines, equipment, and production lines, AI-driven analytics play a crucial role in manufacturing digital transformation. These systems quickly process and interpret data, identifying patterns and trends that help manufacturers optimize production efficiency.

According to the report by Precedence Research, the global market size for AI in manufacturing was $5 billion in 2023 and is forecast to reach $68 billion by 2032. AI is projected to increase productivity by 40% or more in the manufacturing industry by 2035 (Accenture).

AI in Manufacturing market size 2023 – 2034 (Source: Precedence Research)

AI also enhances predictive maintenance, allowing companies to detect anomalies and equipment defects before they cause disruptions. Machine learning algorithms can recognize patterns in data, enabling proactive decision-making and minimizing quality issues early in the production process.

Beyond maintenance, AI is transforming digital transformation in the manufacturing industry by streamlining supply chain management, improving operational efficiency, and proactively addressing workplace safety risks. As manufacturers continue to embrace Industry 4.0, AI-powered solutions are becoming essential for driving innovation and maintaining a competitive edge.

Case Study: Siemens adopted Predictive Maintenance with AI & IoT

Siemens integrated AI-driven predictive maintenance into its industrial machinery through Senseye Predictive Maintenance. By analyzing sensor data in real time, Siemens achieved:

- 40% reduction in maintenance costs

- 55% increase in workforce productivity

- 50% decrease in machine downtime

By proactively predicting machine failures, Siemens improved operational efficiency and saved millions in unplanned downtime expenses. (Business Insider)

Siemens is helping companies in the industrial sector predict machine maintenance problems.

3. 3D Printing

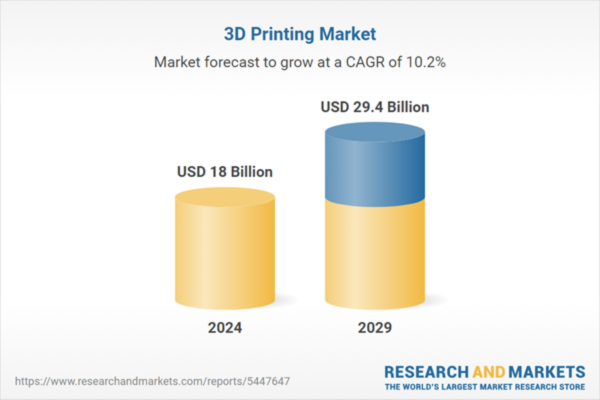

3D printing, also known as additive manufacturing, is transforming the manufacturing industry by redefining how companies design, prototype, and produce products. In smart manufacturing, 3D printing has become a crucial tool for quickly and precisely creating complex parts and components in digital manufacturing transformation.

Traditional manufacturing methods, such as injection molding, often face limitations due to the complexity of part geometry and the multiple steps required for production. With 3D printing, manufacturers can create intricate designs in a single step, significantly reducing manufacturing time and costs.

The 3D printing market is experiencing significant growth, fueled by technological advancements, rising demand for personalized medical solutions, and the adoption of innovative manufacturing techniques across industries. According to Research and Markets, the global 3D printing market is projected to expand from $18 billion in 2024 to $29.4 billion by 2029, reflecting a compound annual growth rate (CAGR) of 10.2%.

3D printing market 2024 – 2029 (Research and Markets)

This technology is particularly valuable in industries like aerospace, automotive, and healthcare, where complex, high-performance components are essential. Additionally, additive manufacturing enables on-demand production of spare parts, minimizing inventory costs and enhancing supply chain efficiency. As Industry 4.0 continues to evolve, 3D printing is becoming a key driver of digital industrial transformation across various sectors.

Case Study: GE Aviation—3D-Printed Aircraft Components

GE Aviation embraced 3D printing (additive manufacturing) as one of the leading digital transformation examples in manufacturing to produce lightweight yet durable aircraft components. By using 3D-printed fuel nozzles in its LEAP jet engines, the company:

- Reduced part count from 20 separate components to 1

- Increased fuel efficiency by 15%

- Manufactured over 100,000 additive components since 2015

This innovation not only cut production costs but also enhanced fuel savings and sustainability in aviation. (Source: GE Aviation)

The manufacturing team in Auburn, Alabama, celebrates its 30,000th 3D-printed fuel nozzle tip for the LEAP engine.

4. Robotics and Automation

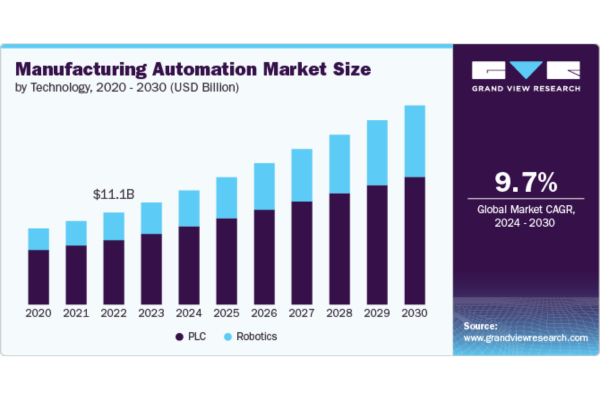

Robotics and automation have been at the forefront of digital transformation in the manufacturing industry for years, and their impact continues to grow. A key driver of smart manufacturing, robotic process automation is revolutionizing production by taking on repetitive or hazardous tasks such as assembly, welding, and material handling.

Futher reading:

The global manufacturing automation market was valued at USD 12.28 billion in 2023 and is projected to grow at a CAGR of 9.7% from 2024 to 2030. This growth is driven by the increasing adoption of Industry 4.0, the commercialization of next-generation networks (NGNs), and a heightened focus on resource optimization and efficiency. Additionally, rapid technological advancements and the integration of new systems and networking architectures are expected to further accelerate market expansion in the coming years. (Grand View Research)

Manufacturing automation market size 2020 – 2030 (Source: Grand View Research)

Advanced robotics technology enhances efficiency by performing repetitive tasks with greater speed, precision, and accuracy than human workers, leading to improved product quality and fewer defects. Manufacturers can make a very flexible and responsive production environment by combining robotics with the Industrial Internet of Things (IIoT) and big data analytics. This is an important part of the digital transformation of manufacturing.

Ultimately, robotic automation improves system efficiency, reduces errors, minimizes equipment downtime, and enhances worker safety. Additionally, robots can operate 24/7, allowing manufacturers to maintain continuous production and significantly boost productivity. As Industry 4.0 continues to evolve, robotics will remain a cornerstone of digital industrial transformation, enabling smarter, faster, and more adaptive manufacturing processes.

Case Study: Foxconn’s Automation Revolution: The Role of Foxbots in iPhone Manufacturing

Foxconn, a leading electronics manufacturer and primary assembler of Apple’s iPhones, has been progressively integrating robotics and automation into its production processes to enhance efficiency and reduce labor costs. The company developed its proprietary industrial robots, known as “Foxbots,” to automate various aspects of assembly.

In recent developments, Foxconn has partnered with UBTech to introduce humanoid robots into its manufacturing processes. The Walker S1 humanoid robots have been undergoing training for logistics operations at Foxconn’s Shenzhen facilities and are expected to be deployed in other factories, including those involved in iPhone production. This collaboration aims to further enhance automation and efficiency in assembling complex electronic devices. (BGR)

iPhone Manufacturer Foxconn Aims for Full Automation of Factories (Source: Fortune)

5. Sustainable Manufacturing

As manufacturing digital transformation progresses, sustainability has become a key focus for modern manufacturers. Traditional manufacturing processes consume vast amounts of energy and water while generating waste and harmful by-products. However, with growing consumer awareness and stricter environmental regulations, companies are under pressure to adopt more sustainable practices.

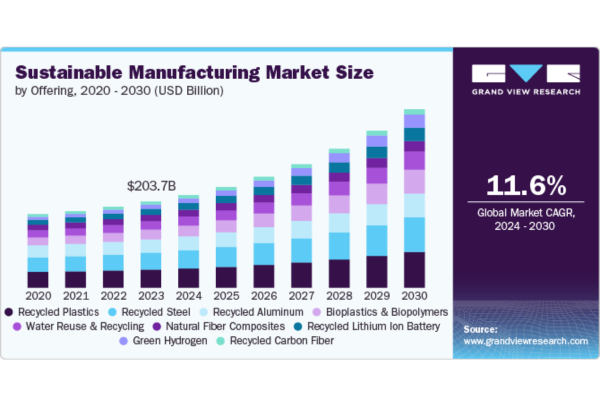

The global sustainable manufacturing market size was estimated at USD 203.65 billion in 2023 and is expected to grow at a CAGR of 11.6% from 2024 to 2030. Growing consumer awareness and preference for environmentally friendly products are driving companies to adopt sustainable manufacturing practices to meet market expectations. (Grand View Research)

Sustainable Manufacturing Market Size 2020 – 2030 (Source: Grand View Research)

Smart manufacturing initiatives now emphasize carbon neutrality and reducing environmental impact. By leveraging digital manufacturing transformation technologies, manufacturers can optimize energy usage, minimize waste, and lower emissions. Strategies such as using renewable energy sources, implementing circular economy principles, and adopting eco-friendly production methods are becoming standard in Industry 4.0.

6. Servitization

As manufacturing digital transformation reshapes the industry, many companies are shifting from simply selling products to offering comprehensive services—a business model known as servitization. In digital manufacturing transformation, this approach includes after-sales services such as maintenance, repairs, and upgrades, helping manufacturers build stronger customer relationships and increase loyalty.

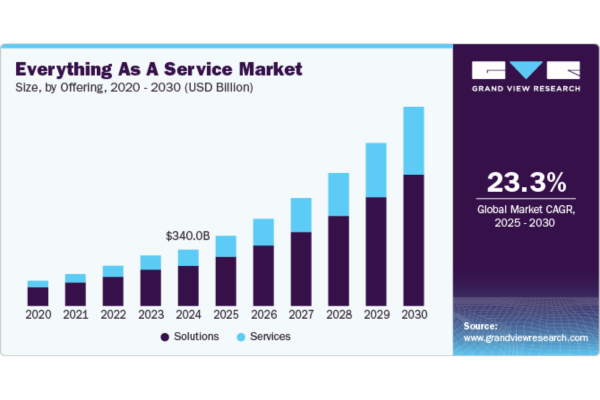

According to Grand View Research’s report, the global Everything as a Service (XaaS) market was valued at USD 340.0 billion in 2024 and is projected to grow at a CAGR of 23.3% from 2025 to 2030. The rising adoption of the XaaS model is driven by the demand for innovative products and services, insight-driven strategies, and digitally powered technology architectures. The shift toward subscription-based models has prompted XaaS vendors to optimize costs and streamline operations. Industries such as media and entertainment, healthcare, BFSI, oil and gas, and IT and telecom are expected to increasingly embrace XaaS solutions.

Everything as a service market 2020 – 2030 (Source: Grand View Research)

By embracing servitization, manufacturers can create recurring revenue streams while differentiating themselves from competitors with value-added services that enhance the customer experience. Additionally, data-driven insights gained from ongoing customer interactions allow businesses to refine product development, improve service offerings, and boost overall customer satisfaction.

In the era of Industry 4.0, servitization is more than just a trend—it’s a strategic shift that aligns with digital transformation in the manufacturing industry, ensuring long-term success in an increasingly service-oriented economy.

Case Studies: Power by the Hour—Rolls-Royce’s Servitization Revolution

Rolls-Royce transformed its business model with TotalCare®, a service package where airlines pay based on engine usage rather than outright ownership. This “Power by the Hour” approach aligns manufacturer and customer interests, replacing the traditional model where repairs generated additional revenue.

By leveraging real-time engine monitoring and predictive maintenance, Rolls-Royce minimizes downtime, reduces unnecessary maintenance, and enhances operational efficiency. This shift has led to widespread adoption, with most of its engines covered under TotalCare® since 2010, proving that servitization creates mutual value through data-driven service innovation.

Rolls-Royce’s Servitization Revolution

7. Reshoring

As manufacturing digital transformation accelerates, many companies are turning to reshoring—bringing manufacturing operations back to their home country. This trend has gained momentum due to factors such as labor shortages, supply chain disruptions, geopolitical risks, and rising labor costs in offshore locations.

Reshoring offers several advantages, including reduced transportation costs, improved quality control, and greater operational flexibility. Additionally, with advancements in smart manufacturing and automation in manufacturing, companies can maintain cost efficiency while enhancing production capabilities domestically.

The U.S. has increasingly focused on bringing critical industries back onshore. For instance, Taiwan Semiconductor Manufacturing Company’s U.S. subsidiary received government funding to establish semiconductor production in Phoenix. As a result, annual manufacturing construction spending in the U.S. surged to $237 billion in July 2024, a significant increase from $128 billion two years earlier, according to U.S. Census Bureau data.

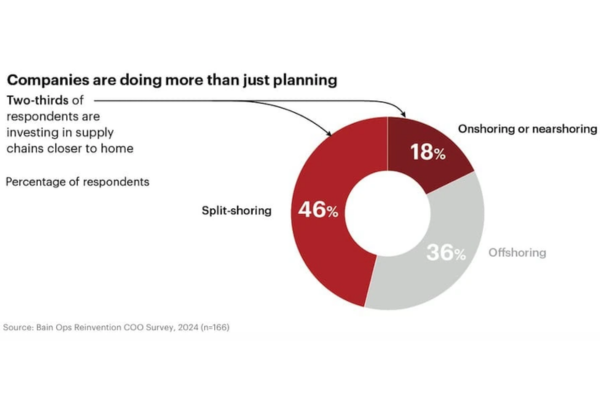

Bain’s research reveals a significant shift in supply chain strategies, with 81% of CEOs and COOs now planning to relocate supply chains closer to their markets—an 18-percentage-point increase from 63% in 2022. Additionally, nearly 64% of executives are investing in split-shoring (46%) or near-shoring (18%), while only 36% continue to invest in offshoring.

Reshoring, Near-Shoring On The Rise (Source: Bain & Company)

Beyond business benefits, reshoring also contributes to local economies by creating jobs and strengthening industrial infrastructure. As Industry 4.0 continues to evolve, reshoring—combined with digital industrial transformation—is becoming a strategic move for manufacturers seeking resilience and long-term growth.

Case Study: Ford’s Reshoring Drive—Powering U.S. Manufacturing for the Future

Ford Motor Company has intensified its reshoring efforts to strengthen domestic manufacturing and reduce reliance on overseas production.

- In October 2024, Ford partnered with LG Energy Solution to produce batteries for the Mustang Mach-E in Michigan, ensuring greater supply chain control and cost efficiency. (ReshoreNow)

- The development of BlueOval City in Tennessee, a high-tech EV and battery manufacturing complex, highlights Ford’s commitment to Industry 4.0 technologies, automation, and sustainability. (CorporateFord)

By reshoring key operations, Ford enhances supply chain resilience, creates U.S. jobs, and solidifies its leadership in the electric vehicle revolution.

Ford to lead America’s shift to electric vehicles with new BlueOval City mega campus in Tennessee and twin battery plants in Kentucky (Source: CorporateFord)

8. Extended Reality (XR)

As manufacturing digital transformation advances, extended reality (XR)—which includes virtual reality (VR) and augmented reality (AR)—is playing a crucial role in bridging the physical and digital worlds. One of the biggest benefits of XR is its ability to enhance employee training and address workforce skill gaps. Smart manufacturing companies use XR to create immersive training simulations, allowing employees to learn new skills in a controlled, risk-free environment. This leads to increased productivity, fewer errors, and safer workplaces.

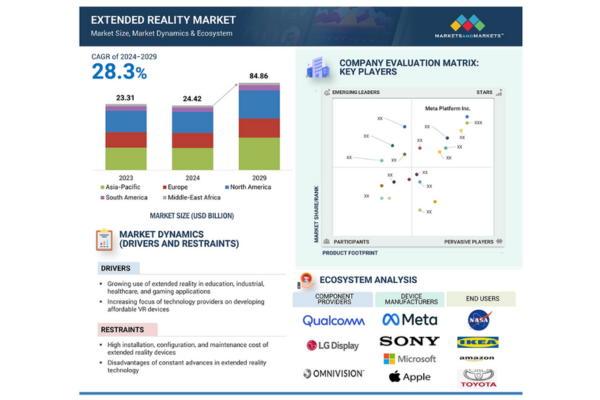

According to MarketsandMarkets, the Extended Reality (XR) market is expected to grow from $24.42 billion in 2024 to $84.86 billion by 2029, with a CAGR of 28.3%. Growth drivers include the rising adoption of XR in education, industrial sectors, healthcare, and gaming. Tech companies are focusing on affordable VR devices, and advancements in spatial computing and generative AI are further accelerating market expansion.

Extended reality market (Source: MarketsandMarkets)

On the consumer side, XR enhances the customer experience by enabling virtual product demonstrations and interactive visualizations. Additionally, XR helps manufacturers improve product design and development by allowing engineers to visualize, test, and refine products in a virtual environment before they go into production. As Industry 4.0 evolves, XR is becoming an essential tool in digital manufacturing transformation, streamlining operations and driving innovation.

Case study: Autoliv China’s Digital Twin Revolution: Transforming Manufacturing with XR and AI

Autoliv China, a leader in manufacturing innovation, partnered with Microsoft and DataMesh to integrate digital twin technology, 3D data visualization, and AI into their operations.

By leveraging Microsoft’s HoloLens 2, they developed a next-generation digital twin platform that enables immersive interaction, hands-free training, and seamless remote collaboration.

This solution has significantly boosted operational efficiency, reduced resource consumption, and enhanced workforce training. Frontline workers can now create applications, modify digital twin scenarios without coding, and optimize maintenance strategies—empowering them to drive innovation across multiple use cases. (Smart Manufacturing Week)

Transforming data-driven work with Microsoft (Source: XR Today)

9. Advanced Materials

As manufacturing digital transformation progresses, the industry is embracing advanced materials such as composites, ceramics, and nanomaterials. These cutting-edge materials offer superior strength, durability, and thermal properties compared to traditional raw materials, making them a key driver of smart manufacturing innovation.

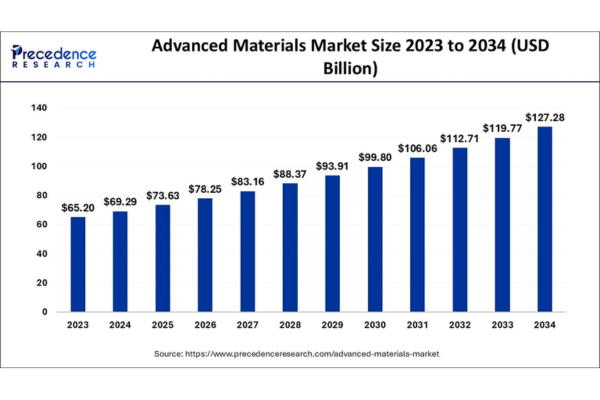

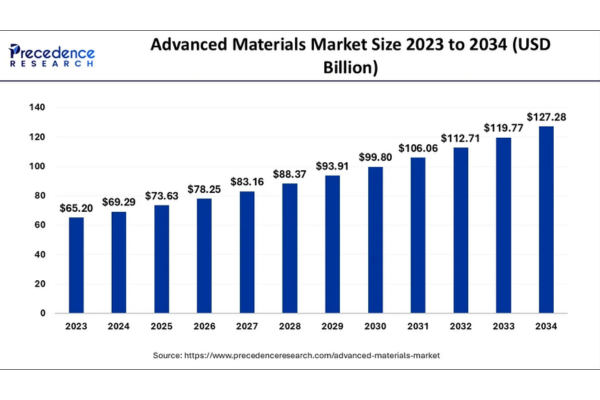

The global advanced materials market was valued at USD 69.29 billion in 2024 and is projected to reach approximately USD 127.28 billion by 2034, expanding at a CAGR of 6.27% over the forecast period. (Precedence Research)

Advanced materials market size 2023 – 2034 (Source: Precedence Research)

Advanced materials are revolutionizing industries like aerospace, automotive, and healthcare manufacturing. For example, composite materials enable the production of lightweight, fuel-efficient aircraft, while nanomaterials are driving advancements in medical treatments and device manufacturing. With the rise of digital manufacturing transformation, these materials are enhancing product performance, reducing waste, and improving sustainability.

As Industry 4.0 continues to evolve, integrating advanced materials with automation in manufacturing and AI in manufacturing will open new possibilities for efficiency, innovation, and next-generation product development.

Case Study: Graphene in Energy Storage—Samsung’s Breakthrough

Samsung Advanced Institute of Technology (SAIT) developed graphene ball technology to enhance lithium-ion batteries, addressing limitations in charging speed, energy density, and lifespan.

Key Advancements:

- 5x Faster Charging: Full charge achieved in 12 minutes compared to nearly an hour for traditional batteries.

- 45% Higher Energy Density: Increases battery capacity, making it ideal for electric vehicles (EVs) and smart devices.

- Lifespan Extension: Retains 78.6% capacity after 500 charge cycles, significantly improving longevity.

- Superior Heat Resistance: Maintains stability at 60°C, a crucial factor for EV safety.

Industry Impact:

- EV Market: Faster charging could help reduce range anxiety, making EVs more practical for mass adoption.

- Consumer Electronics: Enables longer battery life and ultra-fast charging for smartphones, laptops, and wearables.

- Energy Storage Systems: Improves efficiency in renewable energy grids by enhancing battery storage capabilities.

Samsung Develops Battery Material with 5x Faster Charging Speed (Source: Samsung Newsroom)

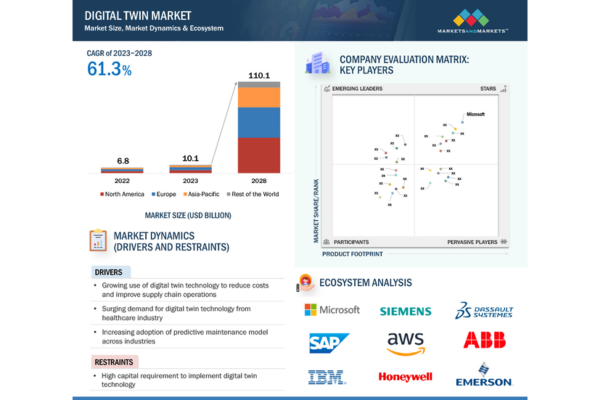

10. Digital Twins

Digital twins are transforming smart manufacturing by providing real-time performance insights through virtual replicas of physical objects, systems, or processes. Equipped with sensors and connected to the internet, digital twins continuously collect data, allowing manufacturers to monitor, analyze, and optimize production operations.

In manufacturing digital transformation, digital twins play a crucial role in improving equipment efficiency, detecting anomalies, and predicting potential failures before they cause downtime. By leveraging IoT in manufacturing, manufacturers can enhance predictive maintenance, improve forecasting accuracy, and optimize production workflows.

Additionally, digital twins enable companies to simulate different scenarios and test configurations before implementing changes in the physical environment. This capability reduces risks, enhances decision-making, and streamlines automation in manufacturing, making digital transformation in the manufacturing industry more efficient and cost-effective.

According to MarketsandMarkets, the global digital twin market is projected to skyrocket from USD 10.1 billion in 2023 to USD 110.1 billion by 2028, expanding at a CAGR of 61.3% during this period.

Companies across various industries are increasingly adopting digital twin technology. Automotive giants like BMW and Renault have integrated digital twins into their manufacturing ecosystems to enhance efficiency. However, its applications extend far beyond manufacturing—it is used for everything from jet production to smart city management, highlighting its vast potential.

Digital twin market 2023 – 2038 (Source: MarketsandMarkets)

As digital twin technology continues to evolve, its adoption is expected to surge across new industries. Key drivers of this growth include supply chain optimization, cost reduction, rising demand in healthcare, and the adoption of predictive maintenance. However, challenges such as complex data management and cybersecurity risks remain hurdles for the industry’s expansion.

Case study: Driving the Future: How NTT’s Digital Twin, AI & Predictive Analytics Revolutionize the IndyCar Fan Experience

Digital twin technology, AI, and predictive analytics are revolutionizing the NTT IndyCar Series, including the legendary Indianapolis 500, by putting fans closer to the action than ever before.

As a partner of Penske Entertainment, NTT harnesses cutting-edge data analytics to enhance the fan experience. By leveraging sensors on Marcus Ericsson’s car and his 32 competitors, NTT has gathered a staggering 8 billion data points—combining insights from previous seasons and the first five races of the current series.

To make this possible, NTT builds a digital twin for every car in the IndyCar Series, powered by a mix of historical data and real-time inputs from 140+ sensors on each vehicle. These sensors capture millions of data points during every race, tracking everything from speed and oil pressure to tire wear and G-forces.

Using AI, digital twins, and predictive analytics, NTT transforms this data into real-time race intelligence, providing fans with deeper insights into head-to-head overtakes, pit stop strategies, and race predictions—bringing them closer to the track with every turn.

NTT’s Digital Twin, AI & Predictive Analytics Revolutionize the IndyCar Fan Experience (Source: Getty Images)

Transform your ideas into reality with our services. Get started today!

Our team will contact you within 24 hours.

Ready to Accelerate Your Manufacturing Digital Transformation?

The future of manufacturing is being shaped by smart technologies, AI-driven insights, and data-powered efficiency. Staying ahead means embracing Industry 4.0 innovations to optimize operations, reduce costs, and enhance productivity.

At Kyanon Digital, we specialize in cutting-edge industrial digital transformation solutions tailored for the manufacturing industry. Whether you’re looking to implement IoT, AI, cloud manufacturing, digital twins, or predictive maintenance, our experts are here to help you navigate the journey.

Why Choose Kyanon Digital for Your Business?

Expertise Trusted by Fortune 500 Clients

With deep experience serving Fortune 500 companies, we deliver tailored, high-impact solutions that meet the unique demands of global enterprises.

A World-Class IT Team

Our 300+ IT experts—spanning consulting, project management, technical architecture, software engineering, QA, DevOps, and AI/ML—are committed to excellence in every project.

Quality at the Core

Certified under ISO 9001, our quality-first approach guarantees precision, reliability, and continuous improvement.

Uncompromising Security

ISO 27001-certified, we integrate robust security into every process, leveraging advanced technologies to protect your data against evolving threats.

Kyanon Digital—One-stop Digital Services House

Let’s transform your manufacturing ecosystem together! Contact Kyanon Digital today to explore how we can drive your business forward.

Key Takeaways

- Smart technologies are redefining manufacturing— Emerging digital transformation trends like AI, IoT, and digital twins are enhancing efficiency, automation, and data-driven decision-making in modern factories.

- Adopting digital manufacturing transformation is crucial—companies embracing these tech trends through cloud computing, predictive maintenance, and cybersecurity gain a competitive edge by optimizing operations and reducing risks.

- The future of manufacturing relies on data-driven innovation— Implementing data analytics in manufacturing helps businesses make smarter, faster, and more informed decisions.

References

Market insights:

- 10 manufacturing trends that are changing the industry, IBM

- Industry 4.0 Market Size, Fortune Business Insights

- Digital Twin Market Size, Share, and Trends, MarketsandMarkets

- 10 manufacturing trends that are changing the industry, IBM Technology

- Artificial Intelligence (AI) in Manufacturing Market Size, Precedence Research

- Artificial Intelligence Poised to Double Annual Economic Growth Rate, Accenture

- 3D Printing Market Size, Share & Industry Analysis, Fortune Business Insights

- Sustainable Manufacturing Market Size, Grand View Research

- IoT in Manufacturing Market, Markets And Markets

- Manufacturing Automation Market Size, Grand View Research

- Everything As A Service Market Size, Grand View Research

- Businesses accelerate reshoring and near-shoring, Bain & Company

- Extend reality market size, MarketsandMarkets

- Advanced Materials Market Size, Precedence Research

Case studies:

- See How BMW Group Is Transforming Manufacturing, NVIDIA

- Siemens’ AI tools are harnessing ‘human-machine collaboration,’ Business Insider

- Manufacturing Milestone: 30,000 Additive Fuel Nozzles, GE Aviation

- Humanoid robots will help build iPhones at Foxconn factories, BGR

- Ford to lead America’s shift to electric vehicles with new BlueOval City mega, Corporate Ford

- Ford inks battery supply deal with LG Energy Solution, Reshore Now

- 9 Insightful XR in Manufacturing Case Studies in 2023, Smart Manufacturing Week

- Samsung Develops Battery Material with 5x Faster Charging Speed, Samsung Newsroom